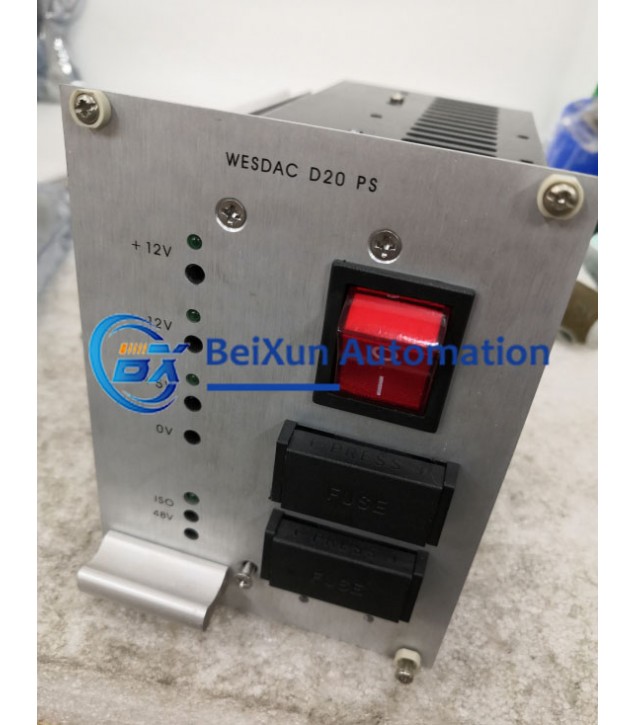

GE WESDAC D20 PS

Industrial Power Supply Module

Product Overview

The GE WESDAC D20 PS is a high-performance industrial power supply module designed for reliable operation in demanding environments. It ensures stable and efficient power delivery to various industrial control systems, making it ideal for applications in manufacturing, automation, and energy sectors.

This power supply module is meticulously engineered for industrial automation environments, ensuring seamless integration and optimal performance. With its robust design, it is capable of delivering consistent and reliable power to critical systems even in harsh conditions.

Key Features

- Stable 24V DC power output

- Wide input voltage range (100-240V AC)

- Overload, overvoltage, and short circuit protection

- High efficiency (>85%)

Applications

- Industrial control systems

- Manufacturing automation

- Energy management systems

- Substation automation

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | WESDAC D20 PS |

| Input Voltage | 100-240V AC |

| Output Voltage | 24V DC |

| Output Current | 10A |

| Power Rating | 240W |

| Efficiency | >85% |

| Output Frequency | 50 kHz |

| Operating Temperature Range | -40°C to 70°C |

| Storage Temperature Range | -40°C to 85°C |

| Relative Humidity | 0 to 95% (non-condensing) |

| Protection Rating | IP50 |

| Dimensions (W x H x D) | 100mm x 80mm x 25mm |

| Weight | 0.5 kg |

Features and Benefits

Wide Input Voltage Range

The 100-240V AC input range allows the module to be used in various regions and environments without the need for additional voltage converters, increasing flexibility and reducing installation costs.

Comprehensive Protection

Equipped with overvoltage, overcurrent, and short circuit protection mechanisms to safeguard both the power supply module and connected equipment from damage caused by electrical faults.

High Efficiency

With efficiency greater than 85%, the module minimizes energy loss and heat generation, reducing operating costs and extending component life.

Wide Temperature Range

Operates reliably in temperatures ranging from -40°C to 70°C, making it suitable for harsh industrial environments where temperature fluctuations are common.

Compact Design

The compact form factor (100mm x 80mm x 25mm) allows for easy installation in space-constrained environments, optimizing cabinet space utilization.

Industry Certifications

Complies with international safety and quality standards, ensuring reliable performance and peace of mind for critical industrial applications.

Applications

Industrial Automation

Provides stable power for PLCs, HMIs, sensors, and other automation components in manufacturing plants and production lines.

Energy Management

Used in power generation facilities, substations, and energy distribution systems to power control and monitoring equipment.

Process Control

Ideal for chemical processing, oil and gas, and water treatment plants where reliable power is critical for process control systems.

Transportation Systems

Suitable for powering control systems in railway, subway, and other transportation infrastructure applications.

Building Automation

Used in HVAC systems, security systems, and other building automation applications requiring stable DC power.

Critical Infrastructure

Deployed in water treatment plants, wastewater facilities, and other critical infrastructure applications where reliability is paramount.

Installation Guidelines

Choose a suitable location with adequate ventilation and away from heat sources.

Ensure the mounting surface can support the module's weight (0.5 kg).

Mount the module in a 19-inch rack or suitable enclosure using standard mounting hardware.

Ensure proper clearance around the module for heat dissipation (minimum 50mm).

Verify that the input voltage matches the module's specifications (100-240V AC).

Make electrical connections according to the wiring diagram.

Double-check all connections before applying power.

Apply power and verify proper operation using the status indicators.

Important: Follow all safety guidelines and local regulations during installation. Ensure the power supply is disconnected before making any electrical connections.

Wiring Diagram

Wiring Notes:

- Use appropriate wire gauge based on current requirements and distance

- Ensure proper grounding for safety and electromagnetic compatibility

- Install a circuit breaker or fuse in the input line (10A recommended)

- Keep AC input and DC output wiring separated to minimize interference

- Use shielded cables for sensitive applications

- Follow local electrical codes and regulations

Maintenance Procedures

Regular Maintenance

- Monthly: Visual inspection for damage or loose connections

- Quarterly: Clean dust and debris from ventilation openings

- Semiannually: Check input and output voltage levels

- Annually: Inspect wiring connections and tighten if necessary

- 2 Years: Replace if operating in harsh environments or high duty cycles

Cleaning Instructions

- Disconnect power before cleaning

- Use a soft, dry cloth to wipe exterior surfaces

- Use compressed air (max 50 psi) to clean ventilation openings

- Avoid using liquids or cleaning solvents

- Ensure the module is completely dry before reapplying power

Replacement Guidelines

- Disconnect input power

- Disconnect DC output connections

- Remove mounting hardware

- Install replacement module using the same mounting location

- Reconnect DC output connections

- Reconnect input power

- Verify proper operation

Troubleshooting

No Output Voltage

- Check input power supply and connections

- Verify circuit breaker or fuse is intact

- Check for loose connections

- Inspect for visible damage to the module

- Test with known good input power source

Output Voltage Fluctuations

- Check input voltage stability

- Verify load is within specified limits

- Check for loose connections

- Inspect for electromagnetic interference

- Check ventilation and cooling

Overheating

- Check ventilation and cooling

- Verify ambient temperature is within specifications

- Check if load exceeds rated capacity

- Inspect for dust or debris blocking vents

- Verify input voltage is within specified range

Intermittent Operation

- Check for loose connections

- Inspect for vibration or mechanical stress

- Check for temperature extremes

- Verify input voltage stability

- Test with reduced load

Note: If the problem persists after performing these checks, contact GE technical support or a qualified service technician for further assistance.

Performance Characteristics

Ordering Information

Model Number

WESDAC D20 PS

Accessories and Options

Power Cord Kit

AC power cord with country-specific plug

Terminal Block Kit

Terminal blocks for secure wiring connections

Surge Protection Module

Additional surge protection for harsh environments

Extended Warranty

1, 2, or 3-year extended warranty options

Disclaimer

General Electric Company reserves the right to modify the specifications contained herein without prior notice. The information provided in this document is believed to be accurate and reliable, but General Electric assumes no responsibility for any errors or omissions.

This product is designed for industrial use only. Any use outside of industrial environments may result in product damage or personal injury.

For the latest product information, technical documentation, and support, please visit the GE website at www.ge.com.

© 2025 General Electric Company. All rights reserved.